10 Ocak 2016 Pazar

Bone Cement

Bone cements have been used very successfully to anchor artificial joints (hip joints, knee joints, shoulder and elbow joints) for more than half a century. Artificial joints (referred to as prostheses) are anchored with bone cement. The bone cement fills the free space between the prosthesis and the bone and plays the important role of an elastic zone. This is necessary because the human hip is acted on by approximately 10-12 times the body weight and therefore the bone cement must absorb the forces acting on the hips to ensure that the artificial implant remains in place over the long term.

Bone cement chemically is nothing more than Plexiglas (i.e. polymethyl methacrylate or PMMA). PMMA was used clinically for the first time in the 1940s in plastic surgery to close gaps in the skull. Comprehensive clinical tests of the compatibility of bone cements with the body were conducted before their use in surgery. The excellent tissue compatibility of PMMA allowed bone cements to be used for anchorage of head prostheses in the 1950s.

Today several million procedures of this type are conducted every year all over the world and more than half of them routinely use bone cements - and the proportion is increasing. Bone cement is considered a reliable anchorage material with its ease of use in clinical practice and particularly because of its proven long survival rate with cemented-in prostheses. Hip and knee registers for artificial joint replacements such as those in Sweden and Norway clearly demonstrate the advantages of cemented-in anchorage. A similar register for endoprosthesis was introduced in Germany in 2010.

Joint Replacement

Replacement arthroplasty (from Greek arthron, joint, limb, articulate, + plassein, to form, mould, forge, feign, make an image of), or joint replacement surgery, is a procedure of orthopedic surgery in which an arthritic or dysfunctional joint surface is replaced with an orthopedic prosthesis. Joint replacement is considered as a treatment when severe joint pain or dysfunction is not alleviated by less-invasive therapies. During the latter half of the 20th century, rheumasurgery developed as a subspecialty focused on these and a few other procedures in patients with rheumatic diseases.

Joint replacement surgery is becoming more common with knees and hips replaced most often. About 773,000 Americans had a hip or knee replaced in 2009.

Titanium carbide has proved to be possible to use combined with sintered polycrystalline diamond surface (PCD), a superhard ceramic which promises to provide an improved, strong, long-wearing material for artificial joints. PCD is formed from polycrystalline diamond compact (PDC) through a process involving high pressures and temperatures. When compared with other ceramic materials such as cubic boron nitride, silicon nitride, and aluminum oxide, PCD shows many better characteristics, including a high level of hardness and a relatively low coefficient of friction. For the application of artificial joints it will likely be combined with certain metals and metal alloys like cobalt, chrome, titanium, vanadium, stainless steel, aluminum, nickel, hafnium, silicon, cobalt-chrome, tungsten, zirconium, etc. This means that people with nickel allergy or sensitivities to other metals are at risk for complications due to the chemicals in the device.

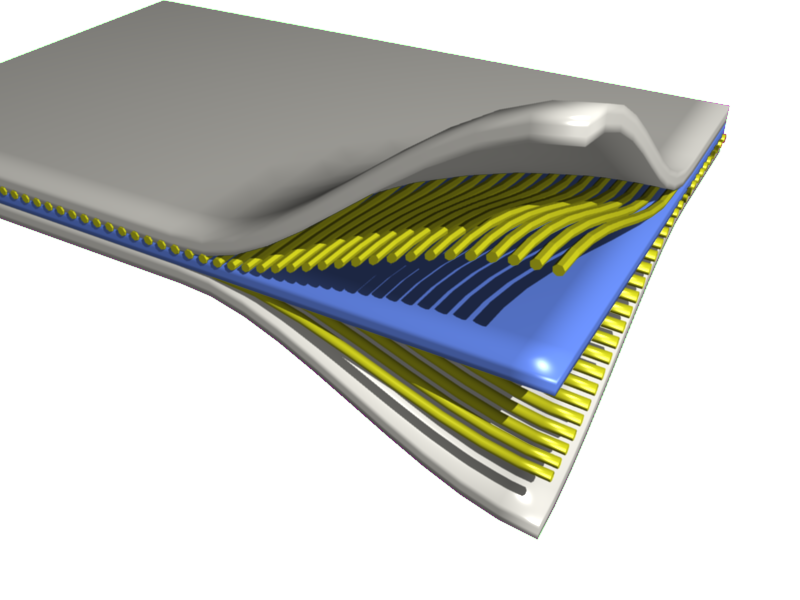

In joints such as knee replacements there are two parts that are ceramic and they can be made of either the same ceramic or a different one. If they are made of the same ceramic, however, they have different weight ratios. These ceramic parts are configured so that should shards break off of the implant, the particles are benign and not sharp. They are also made so that if a shard were to break off of one of the two ceramic components, they would be noticeable through x-rays during a check-up or inspection of the implant. With implants such as hip implants, the ball of the implant could be made of ceramic, and between the ceramic layer and where it attaches to the rest of the implant, there is usually a membrane to help hold the ceramic. The membrane can help prevent cracks, but if cracks should occur at two points which create a separate piece, the membrane can hold the shard in place so that it doesn't leave the implant and cause further injury. Because these cracks and separations can occur, the material of the membrane is a bio-compatible polymer that has a high fracture toughness and a high shear toughness.

Applications of Biomaterials

- Joint replacements

- Bone plates

- Bone cement

- Artificial ligaments and tendons

- Dental implants for tooth fixation

- Blood vessel prostheses

- Heart valves

- Skin repair devices (artificial tissue)

- Cochlear replacements

- Contact lenses

- Breast implants

- Drug delivery mechanisms

- Sustainable materials

- Vascular grafts

- Stents

- Nerve conduits

- Surgical sutures

Structural Hierarchy

Nearly all materials could be seen as hierarchically structured, especially since the changes in spatial scale bring about different mechanisms of deformation and damage. However, in biological materials this hierarchical organization is inherent to the microstructure. One of the first examples of this, in the history of structural biology, is the early X-Ray scattering work on the hierarchical structure of hair and wool by Astbury and Woods. In bone, for example, collagen is the building block of the organic matrix—a triple helix with diameter of 1.5 nm. These tropocollagen molecules are intercalated with the mineral phase (hydroxyapatite, a calcium phosphate) forming fibrils that curl into helicoids of alternating directions. These "osteons" are the basic building blocks of bones, with the volume fraction distribution between organic and mineral phase being about 60/40.

In another level of complexity, the hydroxyapatite crystals are platelets that have a diameter of approximately 70–100 nm and thickness of 1 nm. They originally nucleate at the gaps between collagen fibrils.

Similarly, the hierarchy of abalone shell begins at the nanolevel, with an organic layer having a thickness of 20–30 nm. This layer proceeds with single crystals of aragonite (a polymorph of CaCO3) consisting of "bricks" with dimensions of 0.5 and finishing with layers approximately 0.3 mm (mesostructure).

Crabs are arthropods whose carapace is made of a mineralized hard component (which exhibits brittle fracture) and a softer organic component composed primarily of chitin. The brittle component is arranged in a helical pattern. Each of these mineral ‘rods’ ( 1 μm diameter) contains chitin–protein fibrils with approximately 60 nm diameter. These fibrils are made of 3 nm diameter canals which link the interior and exterior of the shell.

Self-Assembly

Self-assembly is the most common term in use in the modern scientific community to describe the spontaneous aggregation of particles (atoms, molecules, colloids, micelles, etc.) without the influence of any external forces. Large groups of such particles are known to assemble themselves into thermodynamically stable, structurally well-defined arrays, quite reminiscent of one of the 7 crystal systems found in metallurgy and mineralogy (e.g. face-centered cubic, body-centered cubic, etc.). The fundamental difference in equilibrium structure is in the spatial scale of the unit cell (or lattice parameter) in each particular case.

Molecular self-assembly is found widely in biological systems and provides the basis of a wide variety of complex biological structures. This includes an emerging class of mechanically superior biomaterials based on microstructural features and designs found in nature. Thus, self-assembly is also emerging as a new strategy in chemical synthesis and nanotechnology. Molecular crystals, liquid crystals, colloids, micelles, emulsions, phase-separated polymers, thin films and self-assembled monolayers all represent examples of the types of highly ordered structures which are obtained using these techniques. The distinguishing feature of these methods is self-organization.

Biomineralization

Biomineralization is the process by which living organisms produce minerals,often to harden or stiffen existing tissues. Such tissues are called mineralized tissues. It is an extremely widespread phenomenon; all six taxonomic kingdoms contain members that are able to form minerals, and over 60 different minerals have been identified in organisms.Examples include silicates in algae and diatoms, carbonates in invertebrates, and calcium phosphates and carbonates in vertebrates. These minerals often form structural features such as sea shells and the bone in mammals and birds. Organisms have been producing mineralised skeletons for the past 550 million years. Other examples include copper, iron and gold deposits involving bacteria.

Biologically-formed minerals often have special uses such as magnetic sensors in magnetotactic bacteria (Fe3O4), gravity sensing devices (CaCO3, CaSO4, BaSO4) ,biomaterials, iron storage and mobilization (Fe2O3•H2O in the protein ferritin).

Composite Material

Composite material (also called a composition material or shortened to composite) is a material made from two or more constituent materials with significantly different physical or chemical properties that, when combined, produce a material with characteristics different from the individual components. The individual components remain separate and distinct within the finished structure. The new material may be preferred for many reasons: common examples include materials which are stronger, lighter, or less expensive when compared to traditional materials. More recently, researchers have also begun to actively include sensing, actuation, computation and communication into composites,which are known as Robotic Materials.

Kaydol:

Kayıtlar (Atom)